Description

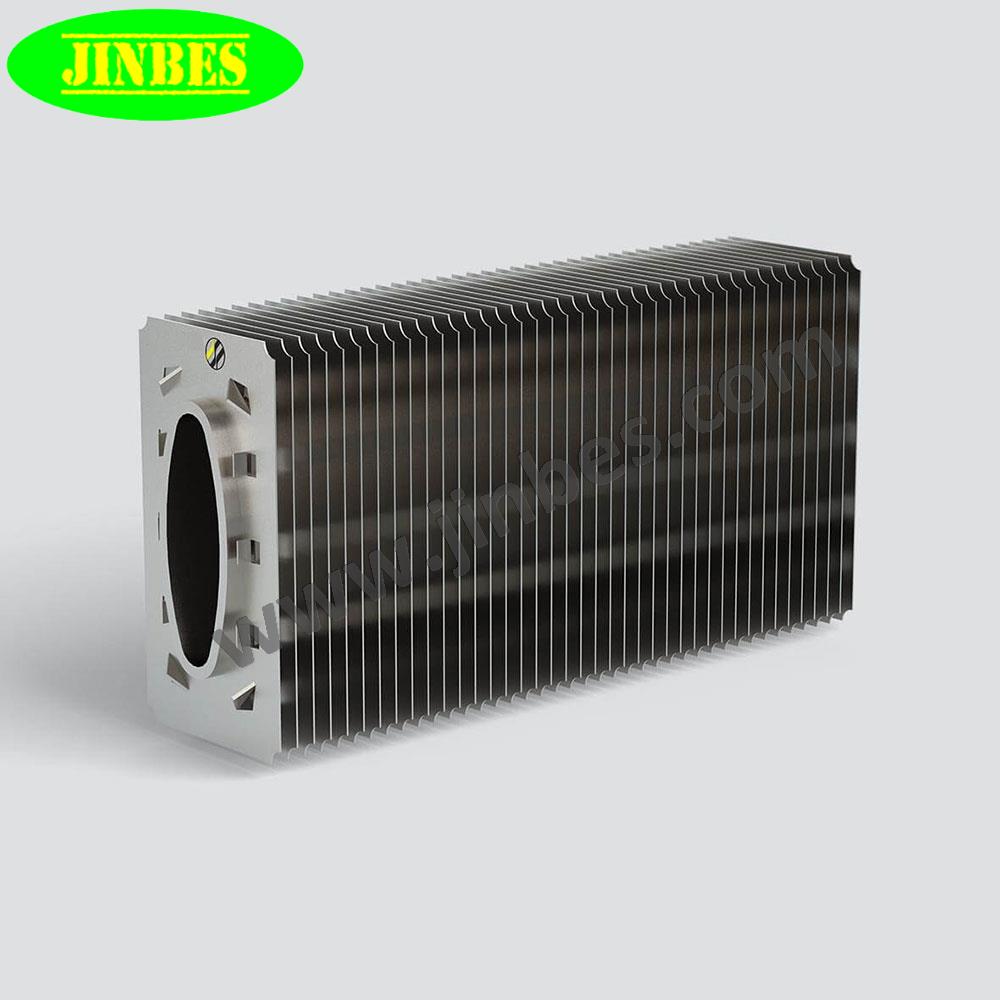

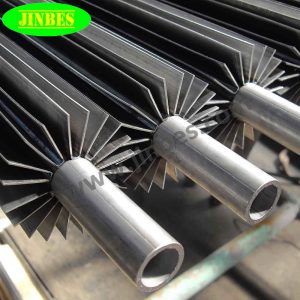

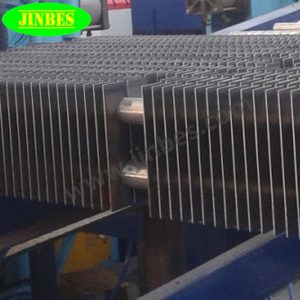

Elliptical finned tube is manufactured by attaching a rectangular fin to a oval tube to significantly increase the heat transfer surface area. Elliptical finned tube has better air flow characteristics than conventional circular finned tube, it is considered as alternatives to circular solid finned tubes in finned tube heat exchanger field. In recent years, it becomes more and more popular in relevant heat exchanger field.

Advantages:

- The reflux zone and windward area is much smaller, reduce the hydromechanics on the air side, then reduce the energy consumption

- Inside the heat exchanger equipment, oval tube bundle is more compact than circular tube bundle, so the heat exchanger has smaller volume and is with lower cost

- The fins are not sensitive to typical mechanical loads, for example hailstorm or walk on the bundles.

- The rectangular fins are with high strength, protecting the base tube from fracture in winter, prolonging the tube life-span.

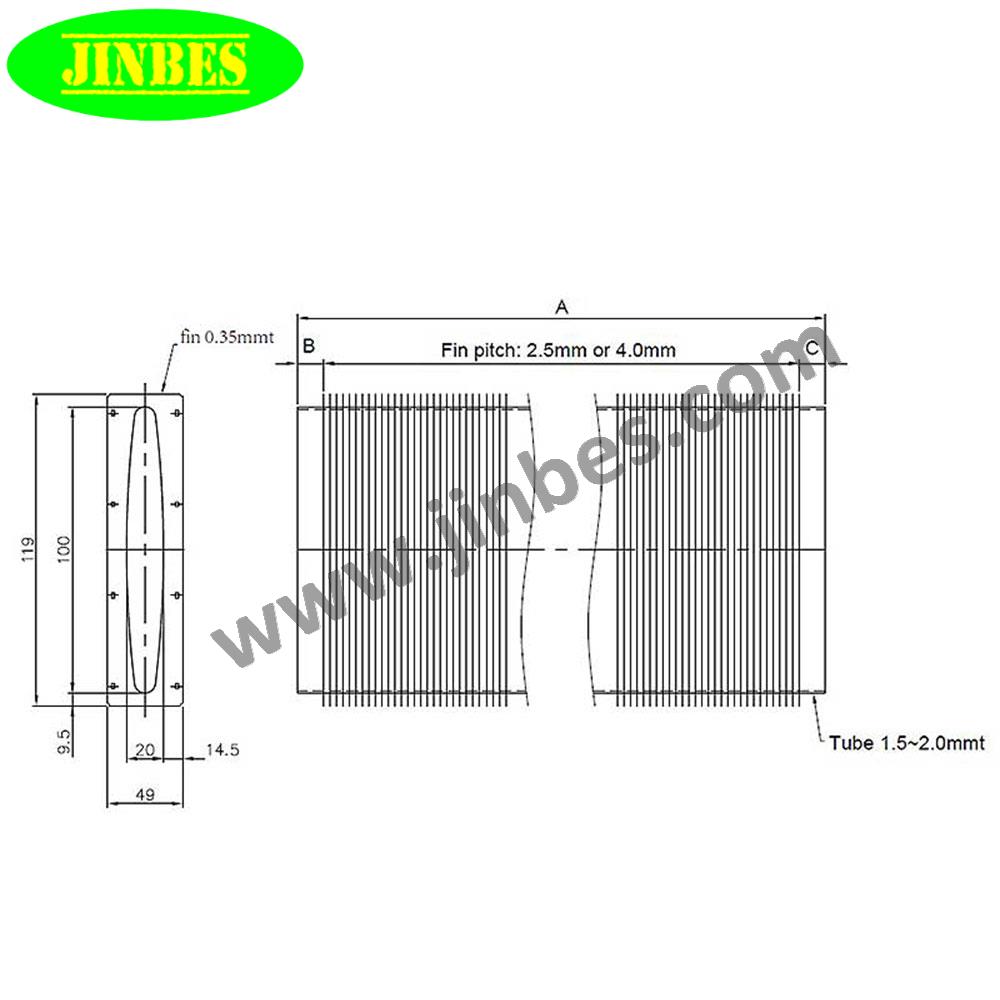

Size of the Elliptical Finned Tube:

Tube Length: Within 25 Meters

Tube cross-section dimension: 36mm*14mm

Tube wall thickness: 2mm

Fin tube cross-section dimension:55mm*26mm

Fin Base Thickness: 0.3mm

Fin Pitch: 416 fins per meter

Finned Tube material:

carbon steel, stainless steel, alloy steel and other materials

Application:

Elliptical finned tube is a new kind of heat exchanger component, it is continuously replace common circular finned tube in some fileds.

Surface Coating:

Hot-dipped Galvanized

Package:

Wooden Package with steel frame

Delivery Condition:

Tube ends are cut with free burrs, internally dried and air-blown clean, externally coated with varnish

Jinbes has one production line for the elliptical finned tube. We also have three sets of cutting machines to cut the finned tubes into different length according to customers’ requirements. If you have any futher design requirements, welcome send us your technical drawings, we can provide our solution for your reference and will try our best to support you.