Description

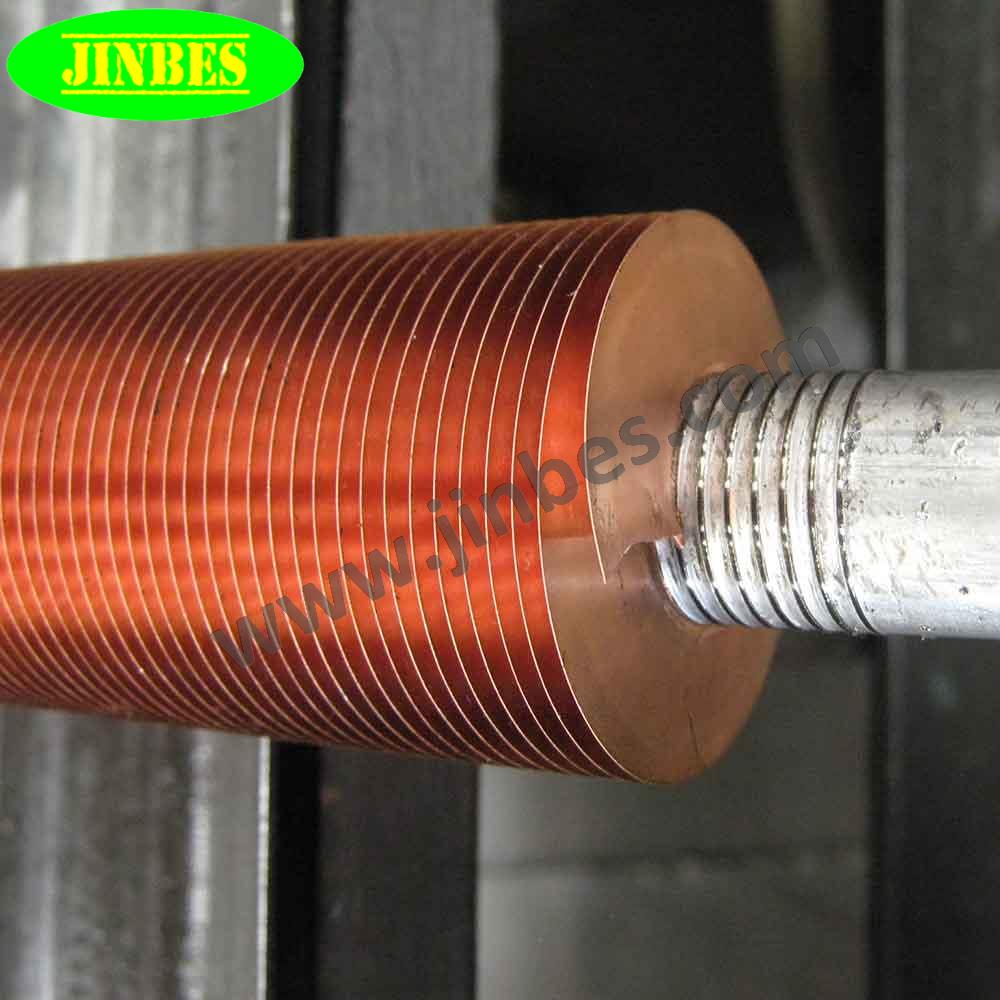

Embedded fin tube is similar with the L/LL/KL type wounded finned tube, but there is a little difference for the base tube. It is made by winding steel, aluminium or copper strip into the helical groove which is processed on the outer surface of the tube. The fins are locked in the groove by strong mechanical bond, which holds up to vibration and continuous thermal cycling.

The advantage of embedded finned tube:

- Embedded finned tube performs very well in such high temperatures because the aluminum fin expands at a greater rate than the base tube and the mechanical bond is very strong.

- It can ensure maximum heat transfer because the heat resistance is much lower than L/LL/KL wounded finned tube

- Its working temperature can up to 450℃, far greater than those for L/LL/KL type wounded finned tube.

G type embedded finned tube size:

Tube OD: from 19.05mm to 50.8mm Tube thickness: 1.65mm Tube material: carbon steel, stainless steel, copper, copper alloy Tube length: within 15 meters Fin material: Aluminium, steel, copper Fins-inch: from 5 to 13 Fins per inch. Fin thickness: from 0.4mm to 0.5mm Fin type: solid

Application:

Embedded finned tube is widely used in heat exchangers which mainly work in high temperature more than 450 ℃。

Package:

Wooden package with steel frame

Delivery condition:

Tube ends are cut with free burrs, internally dried and air-blown clean, externally coated with varnish. Jinbes has six production lines for the G type embedded finned tube and L/LL/KL type wounded fin tube. We also have three sets of cutting machines to cut the finned tubes into different length according to customers’ requirements. If you have any further design requirements, welcome to send us your technical drawings, we can provide our solution for your reference and will try our best to support you.