Description

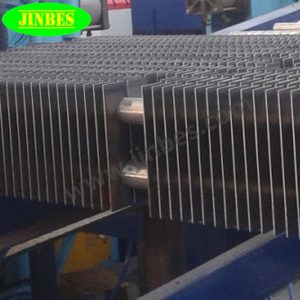

H type finned tube, also called square finned tube, is a common components for the heat exchanger especially for the economizer. It is to weld two symmetrical steel circular on the tubes and the shape is much like a letter “H”. Due to this shape, it can offer larger surface area than normal spiral solid finned tubes.

The advantage of the square fin tube:

- Increase tube outside surface and improve heat transfer efficiency.

- Reduce the number of tubes arranged for the heat exchanger equipments than bare tube.

- Reduce the flue gas velocity and reduce the wear rate and prolong the life-span for the equipment

- H type fins have the best soot blowing effect due to the formation of straight passages on both sides

- Can offer larger surface area than spiral finned tubes

H-Type finned tube size:

Base tube OD: 25mm-65mm

Tube thickness:2.5mm-5.0mm

Fin height: 0.5mm-20mm

Fin thickness: 0.5-3.0mm

H fin size: 324, 325, 384, 385, 425, 485, 515, 516 and customized according to clients’ requirements

Tube material: Carbon Steel, Stainless Steel, Alloy Steel, ND Steel and so on.

Fin material: Carbon steel, alloy steel, stainless steel, aluminium, copper

Application:

H type finned tube is widely used in utility boilers, marine power and the tail of heat exchanger components.

Surface Coating:

Outside red oxide zinc phosphate primer and inside volatile corrosion inhibitor (VCI) in water soluble tablet form

Package:

Wooden Package with steel frame

Delivery Condition:

Tube ends are cut with free burrs, internally dried and air-blown clean, externally coated with varnish Jinbes has two production lines for the H type finned tube and HH type finned tube. We also have three sets of cutting machines to cut the finned tubes into different length according to customers’ requirements. If you have any futher design requirements, welcome send us your technical drawings, we can provide our solution for your reference and will try our best to support you.