Description

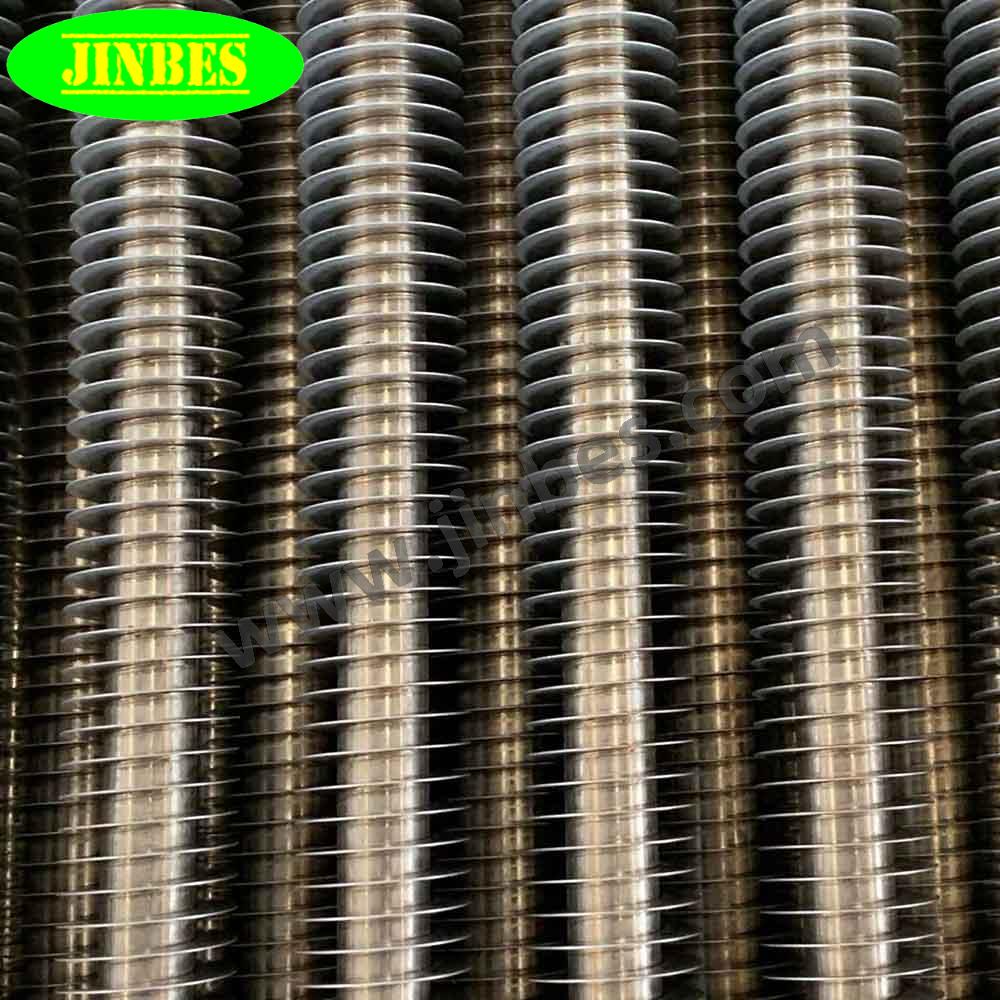

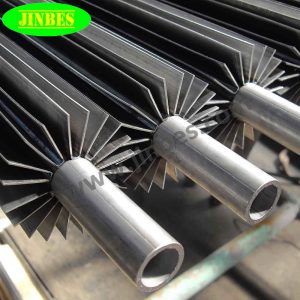

Laser welded finned tube is used in the condenser and heat exchanger, it is often made of stainless steel tube and stainless steel strip, or made of stainless steel tube and copper strip. The solid fins or serrated fins are wound and welded on the tube surface by a automatic laser finning machine, producing a perfect fin-to-tube bond with lower heat input. The laser welded finned tube has good heat transfer performance, as well as other properties like corrosion resistant, abrasion resistant and wear resistant. The complete connection between the fins and the base tube brings about excellent heat transfer and up to 2.5 times higher thermal performance of the finned tubes. With good strength and plasticity, it is also very easy to process.

Advantages

With advanced technology, laser welded finned tube has irreplaceable advantages:

- The base tube’s thickness could be 0.8-1.5mm, and the fin thickness could be 0.3-1.0mm, saving a lot of raw materical cost than other kinds of craft.

- The penetration rate is high, help avoid crevice corrosion, prolong life-span and reduce heat transfer resistance.

- Break the material limitation, laser welded methods can be processed by using different kinds of material.

- Easy to rework, can be coiled and bended directly.

- Welding heat affected zone and metallographic change is small, make it possible for processing the small diameter finned tube.

- The laser welded finned tube is with higher price than other types of finned tube, but the overall holding cost is much lower than others. It is much price saving during its whole life-span.

Dimensions ·

Tube outside diameter 8.0–50.0 mm · Fin outside diameter 17.0 –80.0 mm · Fin pitch 5 –13 fin/inch · Fin height 5.0 –17 mm · Fin thickness 0.4 – 1.0 mm · Maximum tube lengths 20.0 m

Application

Chemical Industry · Heat exchangers of all kinds for cooling and heating of liquids and gases · Heat exchangers tor nitric acid (HNO3) plants, e.g. for the fertilizer industry

Power Plants · Cooling towers or cooling water recooling plants with dry, dry / wet or wet operation · Flue gas cooling and heating in flue gas desulfurisation scrubbers (FGD) and nitrogen removing plants (DENOX)

Heating Industry · Primary heat exchangers in gas heating boilers · Secondary heat exchangers for domestic water heating in condensing boilers

Heat Recovery Plants · Flue gas coolers

General Engineering · Heat exchangers for gas cooling of industrial furnaces · Heat exchangers for tank heating · Oil coolers for vacuum plants, ship plants, pumps etc. · Heat exchangers for oil preheating