Description

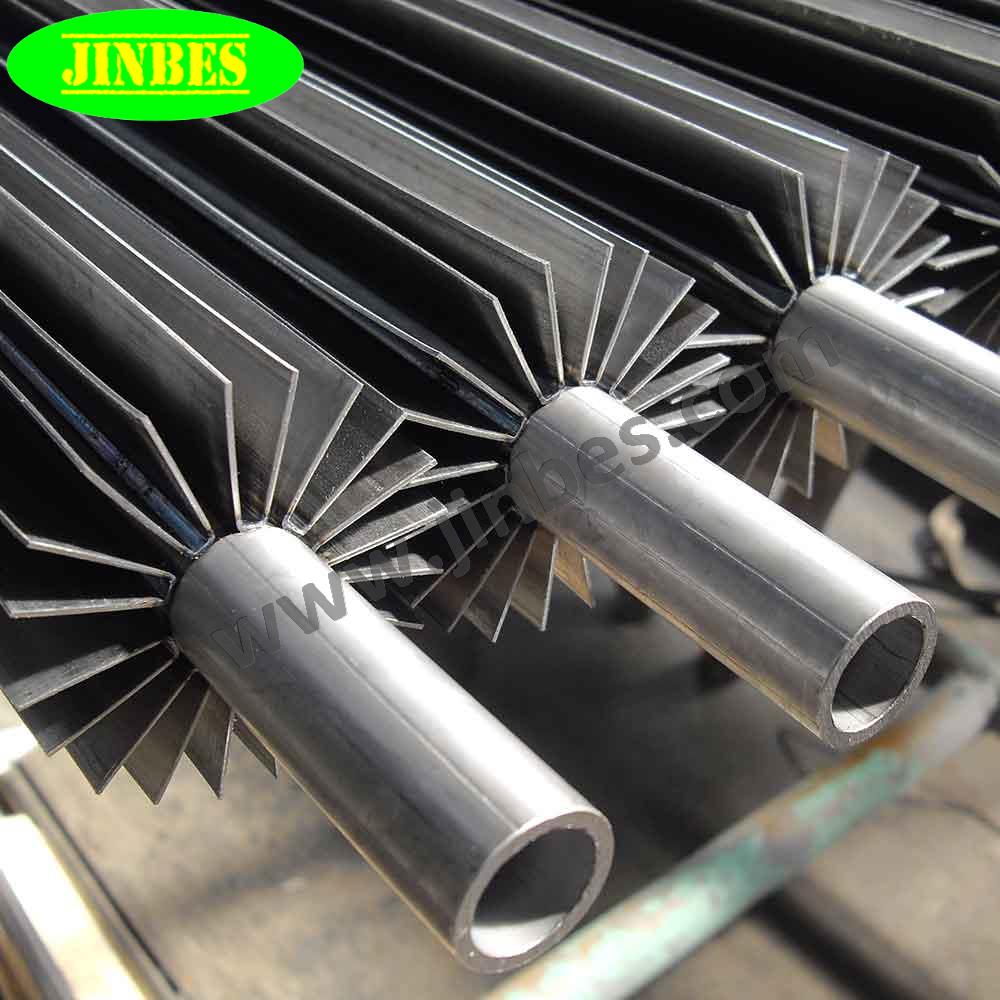

Definition of the longitudinal finned tubes

Longitudinal finned tubes are made of bare tubes and fins. The fins are welded on the surface of the bare tubes, and their orientation are as parallel as the axis of the bare tubes. But what are different with the helical finned tubes, the fins for longitudinal fin tubes are U shape channels or steel flats.

The process methods

The longitudinal fin tubes are produced by high frequency resistance welding method. The U shape fins are formed by punching the steel flats into the U form, so that each leg of the U channel will become a fin for the finned tubes. Then the U shape fins are welded in pairs but in opposite way diametrically. This way makes the fins number are always be in multiples of four, and the maximum fin numbers are depend on the tube outside diameter.

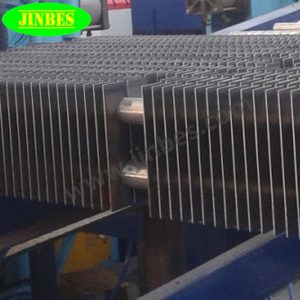

Advantages of longitudinal finned tubes

The welded fin tube makes the fins are highly adhesive to the surface of the bare tubes, making the thermal resistance low, and the finned ratio could be up to above 10, granting a good heat transfer efficiency. At the same time, the structure is simple and much easier than helical to process, minishing the equipment volume, and decrease the equipment cost.

The comparison to the helical finned tubes

The longitudinal finned tube could be used in as many heat transfer applications as helical finned tubes. But due to the geometric configuration are different, the longitudinal ones are also fit in some specific environment besides the normal applications.

For example, when some heaters need to be inserted into other tubes, then the longitudinal fin tubes are much easier than helical fin tubes.

In other case, when the finned tubes are put in vertical direction, the longitudinal fins will be more advantageous because it can help facilitate the fluid while the helical fins would block the fluid flow.

Applications of longitudinal finned tubes:

The longitudinal finned tubes are often used in these applications:

- double pipe heat exchangers

- multi-tube heat exchangers

- heaters

- coolers

And the longitudinal finned tubes can also be customized according to the customer requirements for different industries including oil, power, chemical and petrochemical.

Material grade and size:

Base Tube Size

From 16 mm to 273 mm and more on customized request

Bare Tube Material

Carbon Steel (A106, A333, A179, A210, P5, P11, P22, P9, etc.)

Stainless Steels (304, 316, 321 Duplex, Super Duplex, etc.) +

Copper and Copper Alloys (Brass, Aluminum Brass, Copper Nickel 70/30 + 90/10)

Nickel Alloys (400, 600 and 800 series)

Titanium

Fins Material

Carbon Steel

Stainless Steel

Copper and Copper Alloys

Copper Nickel

Nickel Alloys (400, 600 and 800 series), etc.

Titanium

Fins Height

4.0 mm to 38.1 mm

Fins Thickness

0.8 mm to 1.5 mm

Number of Fins

Depending on the tube OD and customer requirements