Description

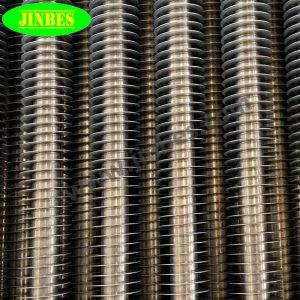

Serrated finned tube is used in the manufacturing of the boiler, pressure vessel and other heat exchanger equipments. The difference between the serrated fins and solid fins are the shape. The serrated fins need one more procedure than the solid fins, that is punch the teeth on the solid strip. The stress on the highest point is bigger than lowest point’s, pulling the teeth open, forming the serrate.

The advantage of the serrated fin tube:

- High heat transfer coefficient. The gas can flow across the serrated fins freely, improving the turbulent motion and enhancing the heat transfer effect. It has about more 15-20% heat transfer efficiency than the solid finned tube.

- Low cost. If transfer same heat amount, serrated finned tube cost less raw material than solid finned tube because of its higher heat transfer effciency, making the procurement cost lower.

- Anti-ash-deposition and anti-scaling. Due to the serrate, it is very hard for the serrated finned tube to deposit the ash and scaling.

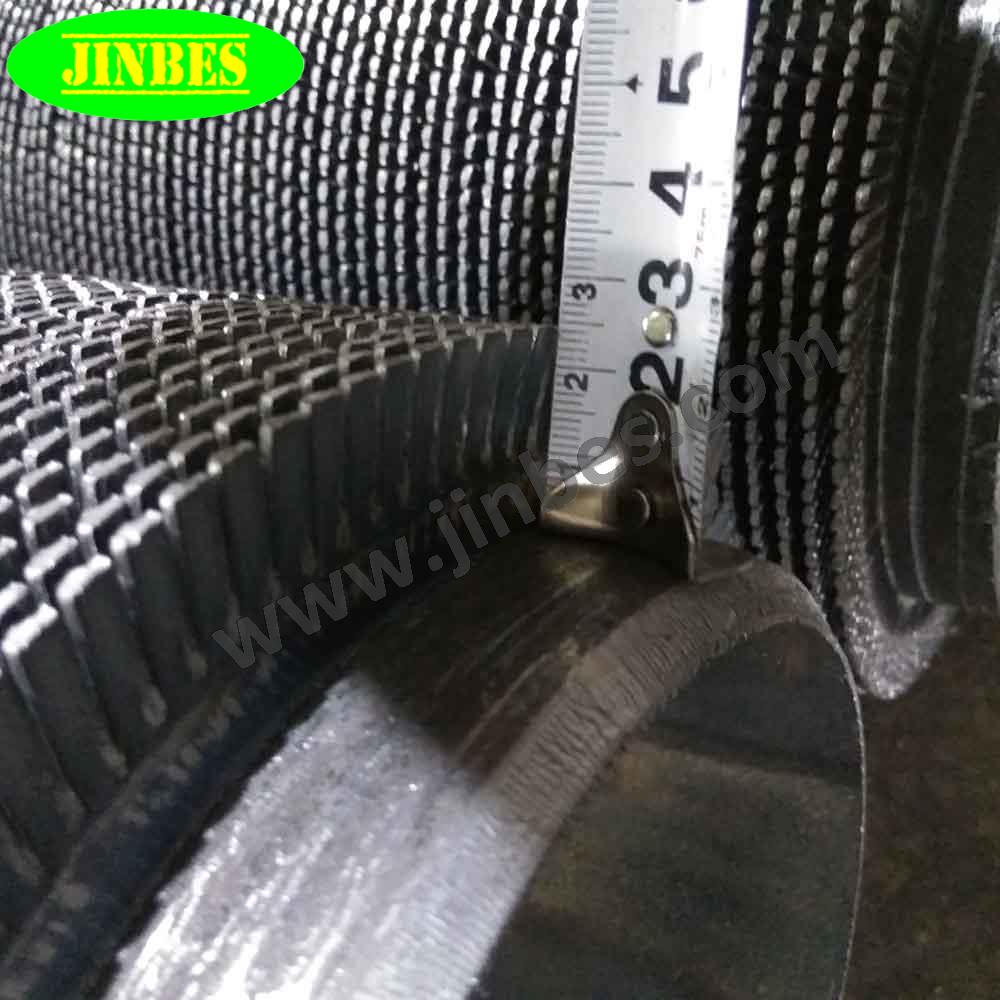

The size of the serrated finned tube:

Tube/Pipe Size: 20mm-323.85mm Fin Height: 6.35mm-32mm Fin thickness: 0.8mm-15mm Fin Pitch: 43-287 fins per inch Material: Carbon Steel, Stainless Steel, Corten Steel, Duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, Ck20 and other materials. Tube Length: Within 25 Meters.

Applications:

The serrated fin tube can be used in high temperature conditions and corrosive atmospheric conditions.

Package:

Wooden Package with steel frame

Jinbes has three production lines for the spiral welded finned tube, can produce the solid finned tube and serrated finned tube. We also have three sets of cutting machines to cut the finned tubes into different length according to customers’ requirements. If you have any futher design requirements, welcome send us your technical drawings, we can provide our solution for your reference and will try our best to support you.