Description

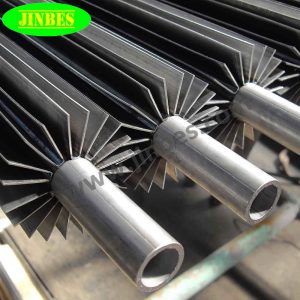

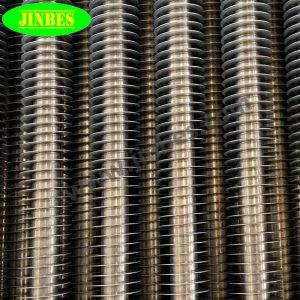

Solid finned tubes are the most common finned tube type for the heat exchanger, covering many kinds of the materials for the base tube and fins. They are manufactured by attaching the continuous helical fin strip around the base bare tube by high frequency electric resistance welding, to increase the outside surface of the tube. The helical solid fins produce a homogeneous, clean, continuous bond for efficieny heat flow and resistance to corrosion. By this way, the heat transfer efficiency is increased, reducing the number of tubes required for the heat exchanger, and reducing the overall equipment size and the project cost. Normally, one finned tube is equal to six or more bare tubes at less than 1/3 the cost and 1/4 the volume. In addition, the production line can also produce the serrated finned tube, just by easily change the solid steel strips into serrated strips.

The size of the solid finned tubes:

Tube/Pipe Size: 20mm-323.85mm

Fin Height: 6.35mm-32mm

Fin Thickness: 0.8mm-2mm

Fin Pitch: 43-287 fins per inch.

Tube Length:Within 25 Meters

Material:

Carbon Steel, Stainless Steel,Corten Steel, Duplex Steel, Super Duplex Steel, Inconel, High Chrome High Nickle & Incolloy, Ck20 and other materials.

Applications:

The HFW solid finned tubes are mainly used in the boilers, coolers, economisers, fired heaters and other heat exchangers for power generation and in furnace applications in the petrochemical industry.

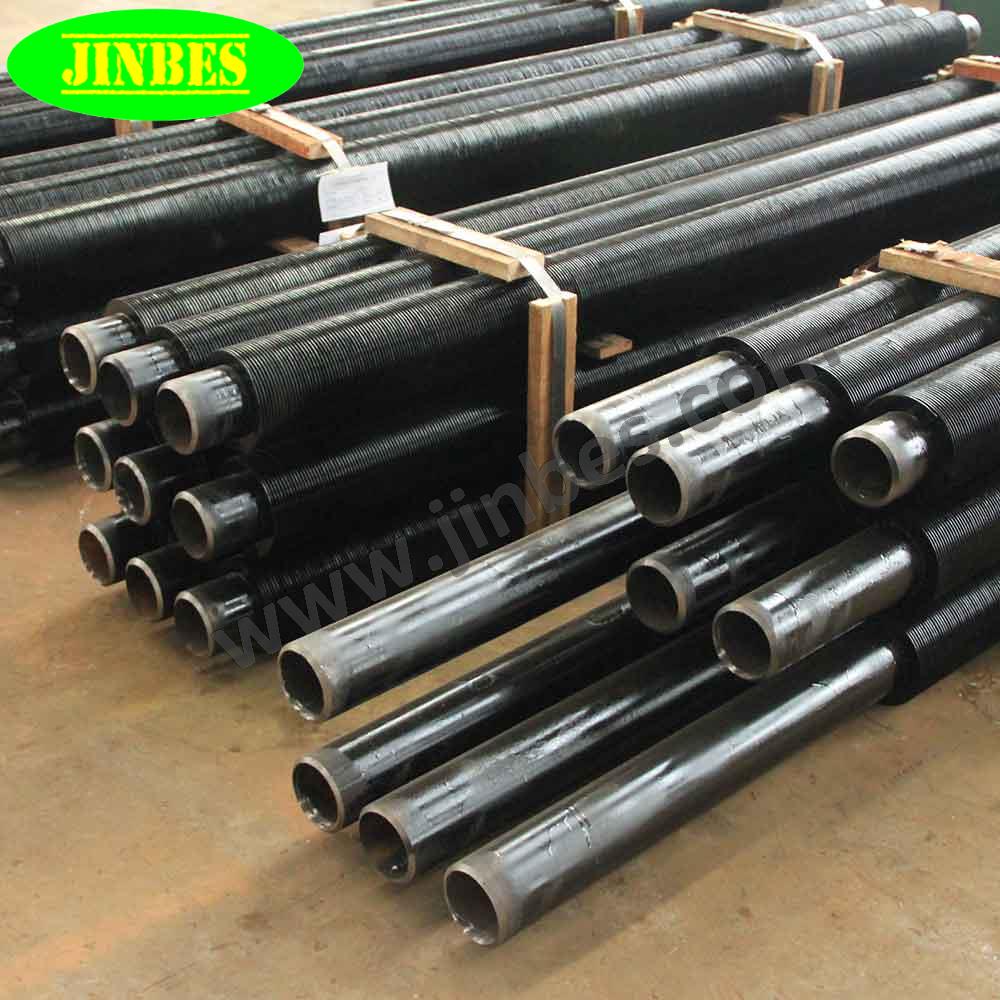

Package:

Wooden Package with steel frame

Jinbes has three production lines for the spiral welded finned tube, can produce the solid finned tube and serrated finned tube. We also have three sets of cutting machines to cut the finned tubes into different length according to customers’ requirements. If you have any further design requirements, welcome send us your technical drawings, we can provide our solution for your reference and will try our best to support you.